| ANSI B 31.1 : POWER PIPING |

| ANSI B 31.3 : PETROLEUM, REFINERY PIPING. |

| ASME SECTION VIII PRESSURE VESSELS |

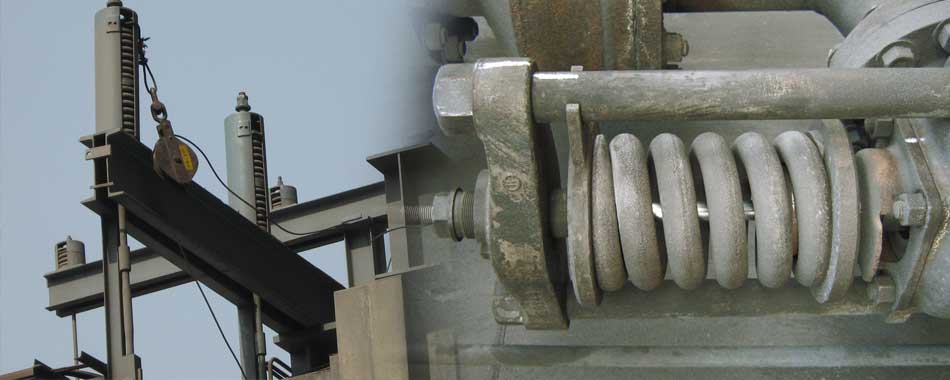

| BS 1726: PART I- GUIDE FOR THE DESIGN OF HELICAL COMPRESSION SPRINGS |

| BS 3974: PART-1, 2, & 3 PIPE SUPPORTS & ANCILLARIES |

| DIN 2092 & 2093 – DISC SPRING |

| MSS SP-58: PIPE HANGERS & SUPPORTS MATERIALS, DESIGN & MANUFACTURING |

| MSS SP-69: PIPE HANGERS & SUPPORTS SELECTION & APPLICATION |

| MSS SP-89: PIPE HANGERS & SUPPORTS – FABRICATION & INSTALLATION PRACTICES |

All design with manufacturing procedures are controlled by formally documented system incorporated in our quality assurance plan and quality system manual in the line of ISO 9000 quality system based on accuracy and the dependability of our product which TECHNO INDUSTRY can provide an efficient service with economical price & prompt delivery to our customers for keeping long time good business relation.?

All design with manufacturing procedures are controlled by formally documented system incorporated in our quality assurance plan and quality system manual in the line of ISO 9000 quality system based on accuracy and the dependability of our product which TECHNO INDUSTRY can provide an efficient service with economical price & prompt delivery to our customers for keeping long time good business relation.?